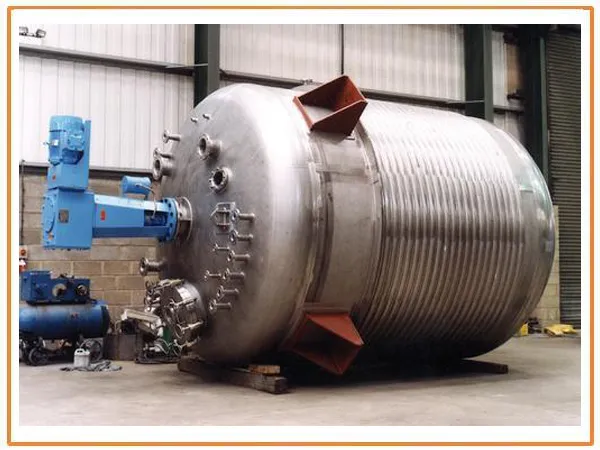

Primesol & Ergo System is well established Reactor Manufacturers in Pune, Suppliers and Exporters in Pune to various industrial applications like pharmaceuticals, chemicals, food processing, etc. They are customized according to different types of reactors and engineered and fabricated to perform par excellence against the best in the industry, with optimal production efficiency in all applications.

A reactor is a vessel or system used in industries like pharmaceutical chemical, and petrochemical, food processing to carry out controlled chemical reactions. It is designed to mix raw materials under specific conditions such as temperature, pressure, and time, to manufacture the desired products. There are multiple type of Reactors like - Jacketed Reactor, Limpeted Reactor, MS Reactor, Reactor Vessel, continuous Reactor, catalytic etc. Depending on the process requirement. They are often produce from SS, Mild Steel or other corrosion-resistant materials for ensuring it's safety and durability. In simple terms, The Reactor is very important part of manufacturing processes, helping to transform raw inputs into valuable end products efficiently and safely.

Our reactors have advanced features such as efficient agitation systems and proper temperature control to perform chemical processes under optimal conditions for a consistent and quality output of the product. The same applies to our Jacketed Reactors, which are ideally suited for stringent control of temperature throughout the whole process, due to their excellent heat transfer design.

We also produce reactors according to specific customer needs, whether they be for small laboratory applications or for very large-scale industrial units. Apart from being known for the best Reactor Manufacturers in Pune, these reactors also find their place in the international markets where it is ensured that they adhere to the world industrial standards.

We are among the top Reactor manufacturers in Pune present an extensive range of high-grade Reactors that are flexible enough to be applied in all types of Reactor as follows:

We have added below a technical sheet of our Reactor that provides more technical information such as:

| Stainless Steel Chemical Reactors | - |

| Max Temperature | 200 |

| Material of Construction | SS |

| Capacity | 1 KL |

| Material | Stainless Steel |

| Usage/Application | Chemical Industry |

| Material Grade | SS316 |

| Mixing Arrangement | AGITATOR |

| Max Pressure | 3-6 kg |

| Reactor Orientation | VERTICAL |

| Size | 1000X1500X1500 |

| Color | ANY |

| Energy Consumption | DEPENDS |

| Finishing | MAT |

| Frequency | 50 HZ |

| Surface Treatment | Galvanized |

| Shape | Round |

| Minimum Order Quantity | 1 |

| Positive Temperatures MS Reactor | 12-15 kg, Capacity 1-2 KL |

| Capacity | 1-2 KL |

| Max Pressure | 12-15 kg |

| Max Temperature | Positive Temperatures |

| Material | Mild Steel |

| Brand | Primesol |

| Color | Customize |

| Usage/Application | Processing Sector |

| Country of Origin | Made in India |

| Mild Steel Reactor Vessel | 500-1000 L |

| Usage/Application | Industrial |

| Capacity | 500-1000 L |

| Material | Mild Steel |

| Max Design Pressure | 10-15 bar |

| SS316/SS 304 SS Reactor Vessel Capacity | 1000-10000L |

| Material | SS316/SS 304 |

| Capacity | 1000-10000L |

| Finishing | Mat/Mirror/Electro polish |

| Orientation | Vertical |

| I Deal In | New Only |

| Country of Origin | Made in India |

| Minimum Order Quantity | 1 |

| Stainless Steel Chemical Reactor: >15 kg | 5 Liter - 30000 Liter |

| Storage Capacity | 5 Liter To 30000 Liter |

| Material Grade | 316/304/M.S |

| Max Pressure | >15 kg |

| Mixing Arrangement | Uniform Mixing |

| Material of Construction | SS, SS316/SS304 |

| Material | Stainless Steel |

| Automation Grade | Automatic |

| Finishing | Mirror/Mat |

| Features | Vertical Orientation |

| Max Temperature | 350 Degree |

| Reactor Orientation | Vertical |

| Power | 0.5 HP to 50 HP |

| Voltage | 440 |

| Color | Required |

| Size | Depends |

| Energy Consumption | Depends |

| Mixer Type | Agitator |

| Vacuum | Full |

| Speed | 10 rpm to 150 rpm |

| Minimum Order Quantity | 1 |

| SS/MS Limpet Reactor | SS 316-304, Capacity >10000 L |

| Material | SS/MS |

| Capacity | >10000 L |

| Material Grade | SS 316-304 |

| Max Design Pressure | 10-15 bar |

| Orientation | Vertical Orientation |

| Quality | GMP/C-GMP Standards |

| Design Type | Standard |

| Tank Orientation Type | Vertical |

| Automation Grade | Automatic |

| I Deal In | New Only |

| Country of Origin | Made in India |

As one of the best Reactor Suppliers in Pune, all types of Reactor are built with advanced technologies and give multiple benefits, such as:

As Reactor Exporters in Pune, our Reactor are highly demanded for multiple types of applications and used for improving performance, such as:

Primesol and Ergo System, Reactor Manufacturers, Suppliers, and Exporters in Pune who develop innovative approaches towards applications of a wide range of chemical and industrial processes. These highly advanced designs in reactors have different consumer focus areas concerning performance, safety, and energy-efficient operation. The high precision and customization were the factors that created trust among both organizations as competitive partners in equipping advances in production in reliable and value-driven reactor systems to industries all over Pune.

Ans: All reactors operate by this inductance principle.

Ans: The very principle of nuclear reactors could be defined as the study of neutron behavior in a nuclear reactor.