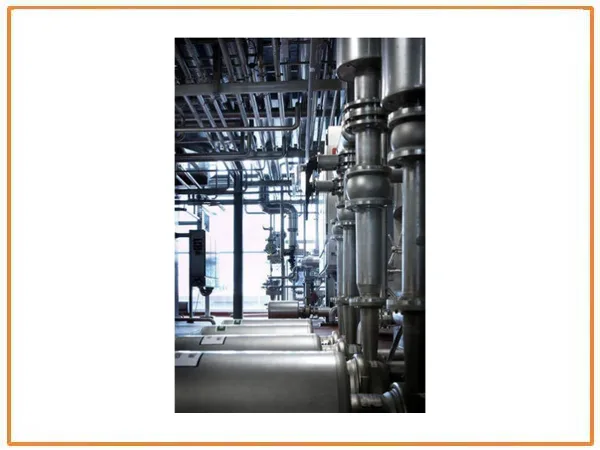

Primesol & Ergo System is a leading name among Food Processing Plant Manufacturers in India, Suppliers, and Exporters in India. They offer world-class solutions to the food and beverage industries. As a result, the Food Processing Plant have been designed to enhance efficiency, quality, and productivity in processing food.

An establishment that processes food is that part of the industry that transforms raw material into packaged commodities through different kinds of machines or chemical or biological processes.

As one of the prominent Food Processing Plant Suppliers in India, we provide a complete line of Food Processing Equipment against all possible applications within the industry. Each and every level of the food processing stage, beginning from raw material handling up to packaging, is partnered with ideal and well-defined installation of equipment for seamless processing and maximum performance.

Maximize the usage of these food processing machineries in high quality grade materials of stainless steel to show that they are long lasting with hygiene coupled with food safety. We have set its portfolio with an array of machines like mixers, grinders, slicers, and packing equipment that ensures efficient and also consistent task results. Our machinery can be counted on state-of-the-art technology to ensure better control, easy operation, and low maintenance, making it most conducive for various applications in food processing.

Primesol & Ergo System is one of the trusted Food Processing Plant Exporters, we continue to provide great solutions for international markets. The food processing plants come with global standards that provide reliable and efficient machinery to the customer, increasing their production capacities. We are known for providing tailor-made solutions to customer needs.

Some of the top Food Processing Plant manufacturers in India present an extensive range of high-grade plants that are flexible enough to be applied in all types of Food Processing Plant as follows:

We have added below a Food Processing Plant of our plant that provides more technical information such as:

| Tomato Processing Plants | - |

| Automatic Grade | Semi-Automatic |

|---|---|

| Design | Customized |

| Type Of Machines | Automatic |

| Capacity | 100 Kg - 10,000 Kg |

| Power Consumption | 20 Hp - 100 Hp |

| Minimum Order Quantity | 1 Unit |

| Fruit Juice Plant Capacity | 500 L - 5000 L |

| Brand | PRIMESOL |

|---|---|

| Material | 304 |

| Capacity | 500 LITER TO 5000 LITER |

| Power Consumption | DEPENDS |

| Machine Type | 3- Stage |

| Output | 500 TO 5000 LITER |

| Machine Power | 40-80 kw |

| Type Of Machines | Fully Automatic |

| Minimum Order Quantity | 1 |

| Tomato Ketchup Plant | - |

| Automation Grade | Automatic |

|---|---|

| Voltage | 440 |

| Surface Finish | Galvanized, Mat |

| Phase | Single, Three/Single |

| Material | Stainless Steel |

| Minimum Order Quantity | 1 PIECE |

| Automatic Stainless Steel Tomato Processing Plant | - |

| Automation Grade | Automatic |

|---|---|

| Material of Construction | Stainless Steel |

| End Product | Pulp/Puree |

| Suitable for | Tomato |

| Voltage | 440 |

| Surface Finish | Galvanized, Mat |

| Phase | Single, Three/Single |

| Mango Processing Plant | - |

| Capacity | Customized |

|---|---|

| End Product | Mango Pulp |

| End Packaging | Canned |

| Automation Grade | Semi-Automatic |

| Material | SS |

| Scope of Supply | Manufacturing, Installation, Commissioning |

| Installation & Commissioning | Primesol Scope |

| Voltage | 440 V |

| Frequency | 50 Hz |

| Power Source | Electric |

| Country of Origin | Made in India |

| Minimum Order Quantity | 1 Unit |

As one of the best Food Processing Plant Suppliers in India, all types of Food Processing Plants are built with advanced technologies and give multiple benefits, such as:

As Food Processing Plant Exporters in India, our plants are highly demanded for multiple types of applications and used for improving performance, such as:

Primesol and Ergo System stand out as prominent manufacturers, suppliers, and exporters of food processing plants, equipment, and machinery in India. We are all about innovation and efficiency in food processing solutions. New technology, therefore, integrates advanced innovative solutions through the quality aspect making great value for money while ensuring that the plants are made to last for time and satisfaction level is very high. On the other hand, sustainable solutions that can be customized, really establish the firms at the top in enhancing food safety, quality, and production efficiency while encouraging the growth of the Indian food processing sector.

Ans: To get rid of micro-organisms (disease-causing) and prolong shelf life to some extent, food is processed.

Ans: This is the diagram that visually summarizes the major stages of food processing: ingestion, digestion, absorption, and elimination.